Key attributes

Product descriptions from the supplier

Your Global Manufacturing Resource

Xiamen Stick Industry Co., Ltd offers the cost-saving advantage for the Manufacture of Customers’ zinc die casting parts requirements.

Stick Industry produces both big & small precision Zinc Die Casting parts/components for wide variety of market applicants, including :

1. Lock hardware parts

2. Furniture parts

3. Machine & equipment parts

4. Door & window hardware parts

5. Bathroom accessory

6. Auto parts

Products Show

Industrial parts

Our Company

With plentiful experience and skillful technique, Xiamen Stick Industry Co., Ltd produce good quality zinc die casting and zinc gravity die casting as per our customer’s drawing or sample.

We have a comprehensive production line, and equipped with advanced facilities.

The Factory is consist of the below departments, as Casting Dept, CNC Machining Dept, Polishing Dept and Plating Dept etc.

Equiped with 8 hot chamber zinc die casting machines, our production capacity is over 500,000 pcs per month.

CNC Machining Workshop

Drilling, Milling, Tapping,CNC Machining , Deburring ect

Polishing Department

We have more than 20 sets manual polishing machines and 2 auto polishing Lines .

Plating Department

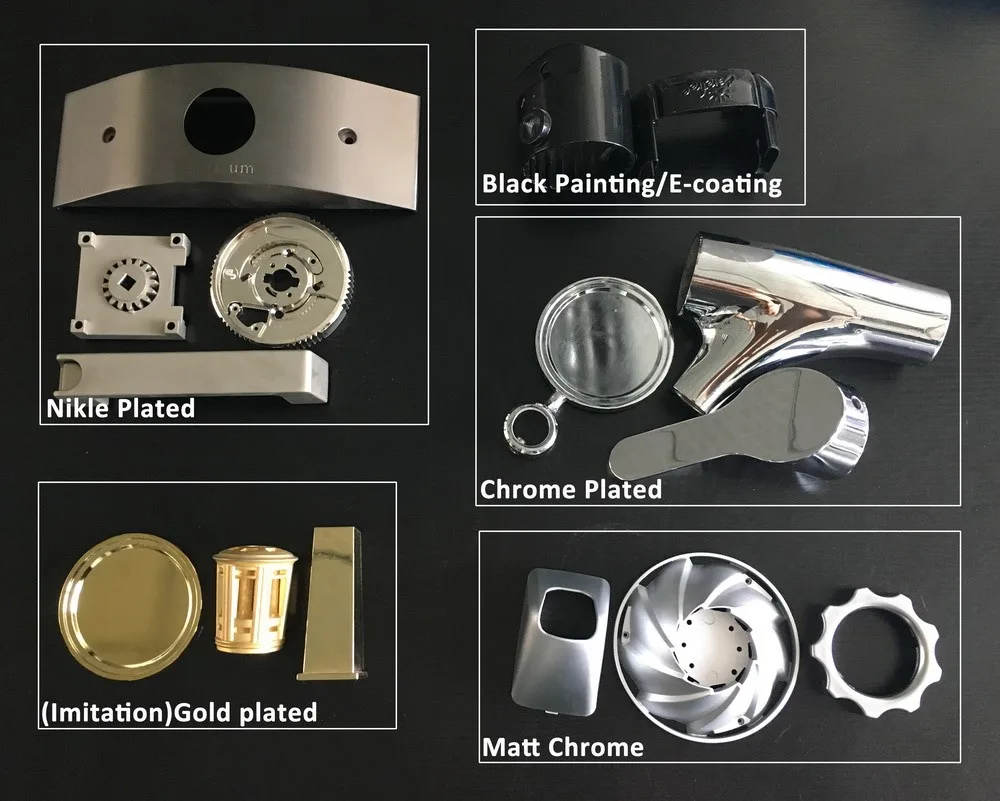

Our plating line can make various plating surface treatment to meet client’s request. Such as bright chrome, matt chrome, Nickle, Pearl Nickle, Gun metallic etc

The plating surface treatment of the part we do can pass the RoHS testing

Ref. Surface Treatment:

Packing & Delivery

Our Certifications

Our Team

Q: Are you trading company or manufacturer ?

A: We are factory. We are experienced manufcturer, have our own factory and warehouse.

Q: What do we need if you want a quote?

A: Please kindly send us your 2D & 3D drawing of your product. The need the detail specifications as follows :

1. Material

2. Surface treatment

3. Estimated production volume

Q:How does the payment process work ?

A: Our preferntial payment term is T/T

Mould Tooling : 50% down payment, 50% balance against the sample approval.

Mass Production: 50% down payment , 50% against the B/L copy .

Q: How do I know about the production ?

A: We will double confirm your requirements and send you the samples before the mass production .

During the mass production , we will keep you informed of any progress.Besides, we will do 100% quality inspection

before shipment

Q:How do we know about the deliery status ?

A: We will immediately inform you the tracking number once we get it from shipping agent. Besides, we will update the latest shipping information.